Description

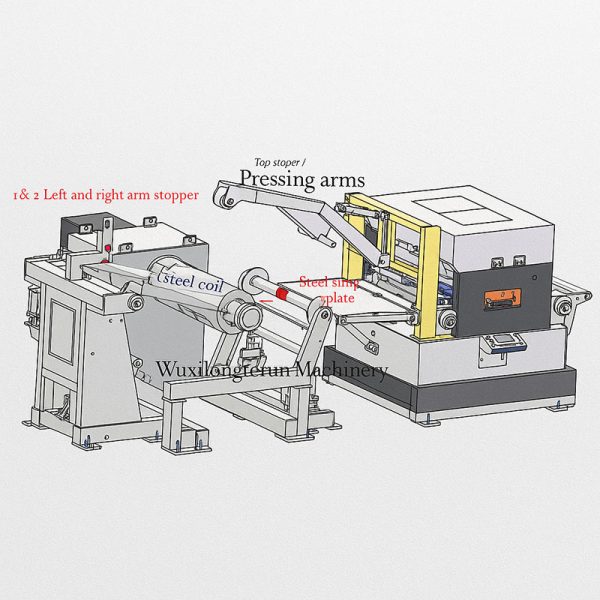

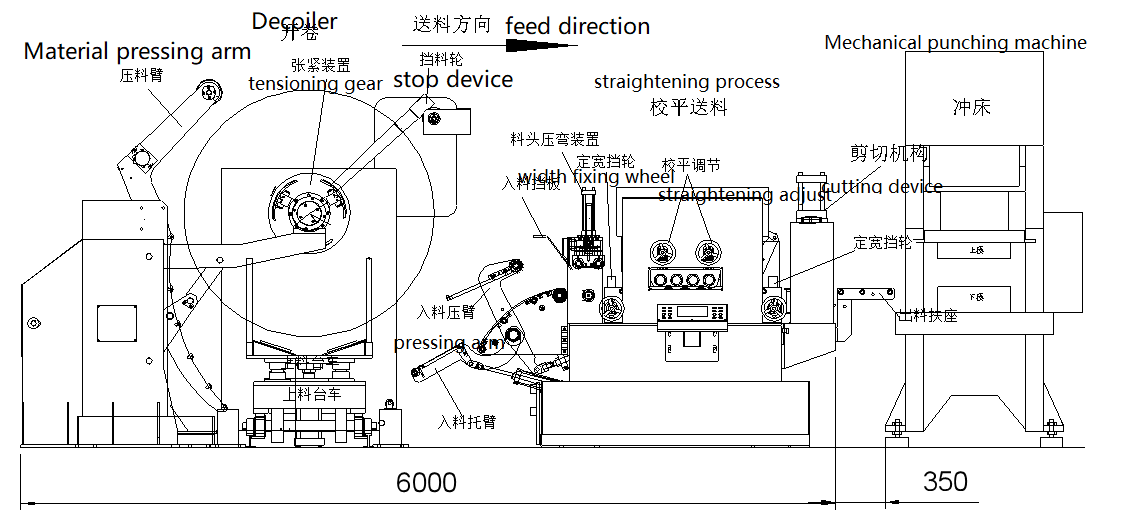

Mechanical decoiler, straightening, and blanking line

Material thickness: 0.6-6mm

Material width: 200-1300mm

Material feeding speed: 16m/min

Material ID/OD: 508mm/1500mm

Straightening roller: ¢90(Up 5 low 4), with one set support roller

Material conveyor: ¢115*1 set, with one set support roller

Coil weight: Max. 15Ton

Feeding direction and height can be adjustable.

Straightening adjust: servo driven, digital show.

Rack motor: 7.5KW, servo motor: 7.5KW

Feeding trolley working table size: 1250*800mm

Feeding trolley lifting distance: 350mm(suitable for 1000-1500mmOD coil)

Main electric components brand:

Decoiler:

Mechanical punching machine/mechanical blanking line:

| No | Description | Brand |

| 1 | Photo electricity material arc control system | Taiwan Yangming |

| 2 | Coil rack converter | Taiwan Shilin |

| 3 | Main release air cylinder | Airtac |

| 4 | Pneumatic electromagnetic valve | Airtac |

| 5 | Straightening bear | Japan NSK |

| 6 | Servo driver | Japan YASKAWA |

| 7 | Servo motor | Japan YASKAWA |

| 8 | Touch screen – 7 inch | MCGS |

| 9 | PLC program controller – FX | Mitsubishi |

| 10 | Breaker | Zhejiang Zhengtai |

| 11 | Contactor | Schneider |

| 12 | Control button | Schneider |

| 13 | Relay | Omron |

| 14 | Cycloidal pin wheel reducer | Zhejiang Yongjia |

Our Service

* Sample testing support.

* View our Factory.

* Training how to install the machine, training how to use the machine.

* Engineers available to service machinery overseas.

FAQ

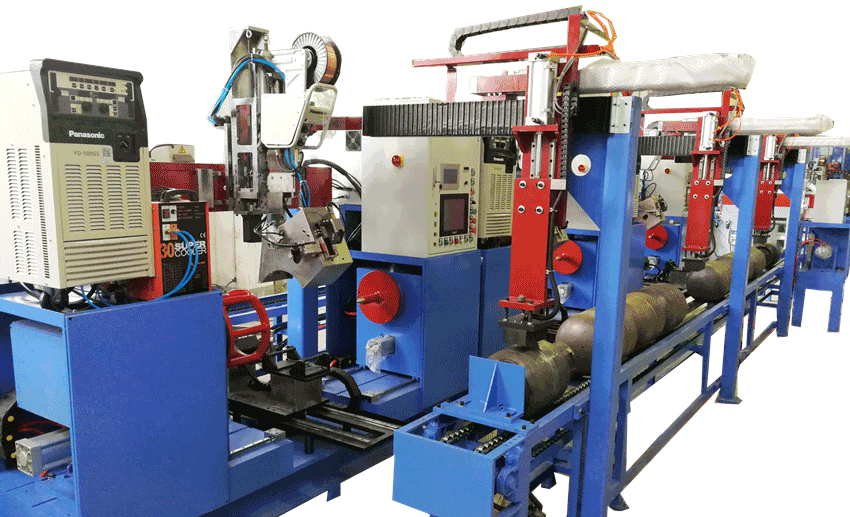

LPG cylinder manufacturing equipment

Q: What size of LPG cylinder your machine can produce?

A: 6kg, 12kg,15kgs and 50kgs LPG cylinder for cooking and other size according customers’ requirement.

Q: Can you design machines according LPG cylinder technical drawing?

A: Sure, please send your technical drawing to us.

Q: What are the benefits to choose your machines?

A: Our machines are strong and reliable for long term industrial manufacturing

To enable me give you correct proposal for correct machines, please tell me following details:

We need to know following information to quote you correct machineries:

1. What size cylinder for making?

2. Capacity of each cylinder per hour?

3. Cylinder drawing?Or what material and thickness and diameter steel disc will for making?

4. Budget?