Description

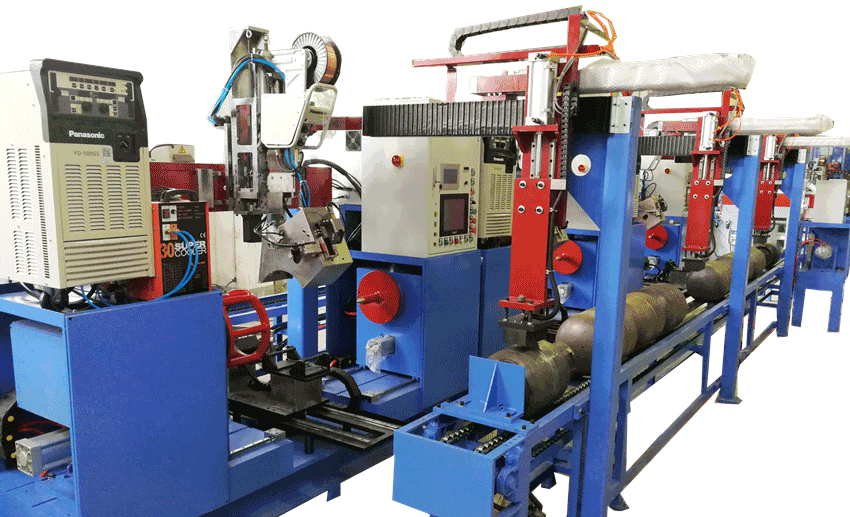

Application:

Backing welding of cladding, backing welding of stainless steel on carbon steel or low alloy steel.

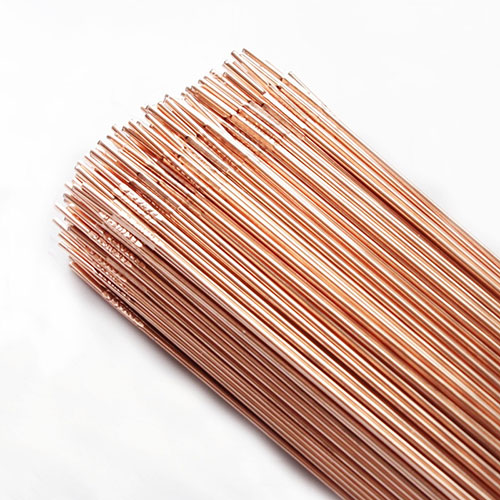

Characteristics:

The welding wire is ultra-low carbon stainless steel flux cored wire. The carbon content of the deposited metal is less than 0.04%, which has good intergranular corrosion resistance. The weldability is excellent, and the deposited metal has good mechanical properties. The welding wire has the advantages of small spatter, easy slag removal, beautiful shape, and all-position welding. The welding wire has been certified by CCS, ABS, and classification societies of both countries.

Attention:

1. Reverse DC connection.

2. The extension length of the welding wire is 1520m, and the Co. gas flow rate is 20 25L / mini3. The interlayer temperature is ≤ 120 “C in multi-pass welding.