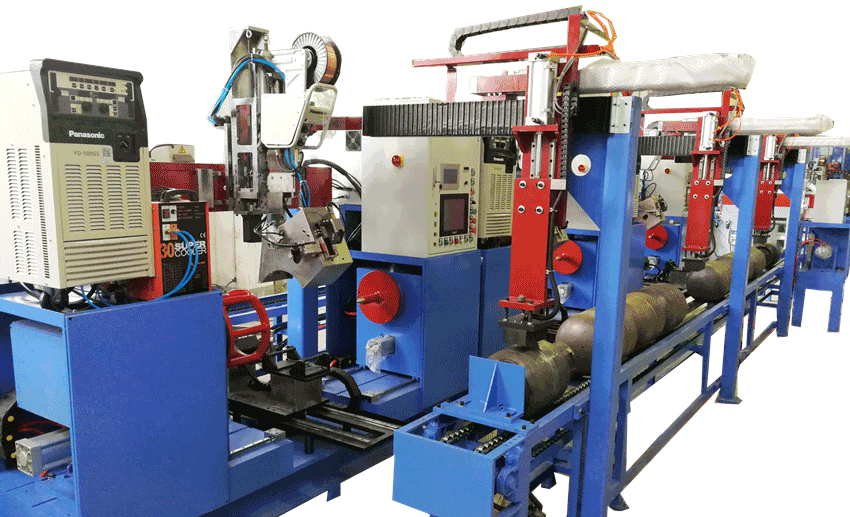

- LPG Cylinder Electrostatic Powder Coating Line

Max. workpiece size: Φ300xH570mm, Φ360xH1055mm

Workpiece weight: ≤35kg

Braced chain: QXT250/50Kg light chain

Machine capacity: 250pcs/hour

Heating source: Nature gas

Hanging type: One cylinder every two pitches, which means one cylinder per 500mm

Using color-changed single-grade filter core recycling powder room.

- 1. Configuration(1) Powder coating room

The shell of the powder coating room is made of high-quality stainless steel, the side sheet thickness is 1.5mm, the top gate thickness is 1.5mm, and the bottom of the powder coating room uses a metal support structure. The powder coating room is equipped with floodlights, luminance is 500 Lux.

The powder coating room is equipped with a manual spraying opening, it can be used for pre-spraying and repair spraying. The light color of the powder coating room and the integration lighting guarantee excellent working conditions, the operators can enter into the powder coating room and clean the room with an extended air suction pipe.

(2)Filter cartridge recycling device

The back filter cartridge is used for splitting the micron powder from the air that is sent by the cyclone separator. In addition, the recycling fan guarantees the constant wind speed of the powder coating room. The material of filtration uses Toray. The air drained by the fan can drain into the workshop. Airflow: 11000m3/h, motor power: 11KW, filter area: 165m2, compressed air consumption: 22 Nm3/h.

Filter control instrument is the intelligent control system using a cartridge recycling reverse blowing device, it can not only control the pressure of the filter inside/outside automatically, but once the pressure reaches the pre-set point, the system will start the filter pulse blowback cleaning process automatically, but also has automatic optimize function, with the increase of working time, the filter control instrument will realize the filter pulse blowback according to the optimize process automatically. This system can save the consumption of compressed air greatly, extend the cartridge working life, reduce the manual cleaning number, and lower the equipment noise at the same time.

Back filter cartridge recycling device incl.:

1. The back filter cartridge device is equipped with a shell.

2. Filter device equipped with cartridge, fan impulse type filter

3. Filter

4. Clean air outlet equipped with muffler

5. Residual powder collection box and vibrating screen

6. Air storage tank

2. Spray gun

Total: 1 set manual spray gun, 2 sets automatic spray gun, 6 sets fixed spray gun.

FAQ

LPG cylinder manufacturing equipment

Q: What size of LPG cylinder your machine can produce?

A: 6kg, 12kg,15kgs and 50 kg LPG cylinders for cooking and other sizes according to customers’ requirements.

Q: Can you design machines according to the LPG cylinder technical drawing?

A: Sure, please send your technical drawing to us.

Q: What are the benefits of choosing your machines?

A: Our machines are strong and reliable for long-term industrial manufacturingTo enable me to give you the correct proposal for the correct machines, please tell me the following details:

We need to know the following information to quote you the correct machinery:

1. Technical Drawing of the cylinders you want to make?

2. What size of cylinder you want to produce? (6kg, 12kg)

3. What diameter and thickness of the cylinder do you want to make?

4. Are you new in this area or do you already have some machines in the workshop?

5. Capacity you require, i.e. how many pieces and sizes do you want to make per day?

Longterm Machinery

Professional LPG Gas Cylinder Production Line Manufacturer

Contact information

WhatsApp/Cellphone: +86-15052276858, 13182761356 Skype ID:Kellyhuang7110 Wechat:+86 15052276858

kelly.huang@longtermmachinery.com / kily_li3@126.com