Description

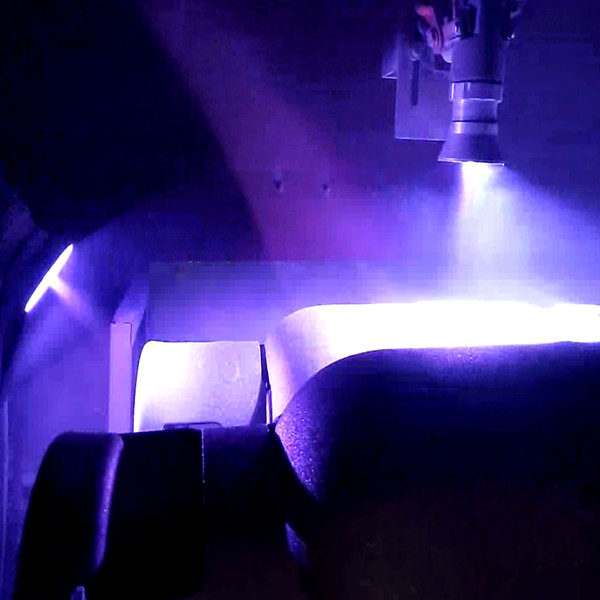

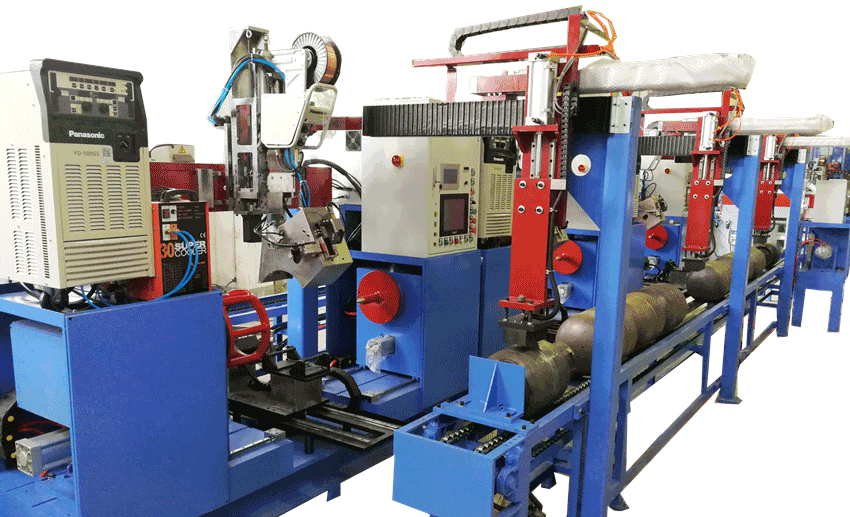

Zinc metalizing line for LPG cylinder production line

- Arc spraying zinc machine total power: 15KVA*N

- Vacuum cleaner engine power: 5.5KW

- The compressed air input pressure: 0.55~7Mpa

- Diameter of the zinc wire: 2-3mm

- Rated input voltage: 220V~280V

- Productivity: 60 pcs/hour

- Zinc wire consumption: 93 kgs/hour

3. Main structure and function

- Oven(1 room)

- Arc spraying zinc machine(3 sets)

- Hydraulic pressure station(1 set)

- Vacuum cleaner and fan(1 set)

- Spraying gun clamp

- Oil cylinder

FAQ

LPG cylinder manufacturing equipment

Q: What size of LPG cylinder your machine can produce?

A: 6kg, 12kg,15kgs and 50kgs LPG cylinder for cooking and other size according customers’ requirement.

Q: Can you design machines according LPG cylinder technical drawing?

A: Sure, please send your technical drawing to us.

Q: What are the benefits to choose your machines?

A: Our machines are strong and reliable for long term industrial manufacturing

To enable me give you correct proposal for correct machines, please tell me following details:

We need to know following information to quote you correct machineries:

1.Technical Drawing of the cylinders you want to make?

2.What size of cylinder you want to produce?(6kg, 12kg)

3.What diameter and thickness of the cylinder you want to make?

4.Are you new in this area or you already have some machines in the workshop?

5.Capacity you require, i.e. how many pieces and sizes you want to make per day?